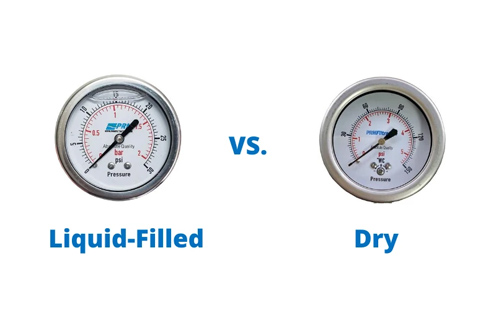

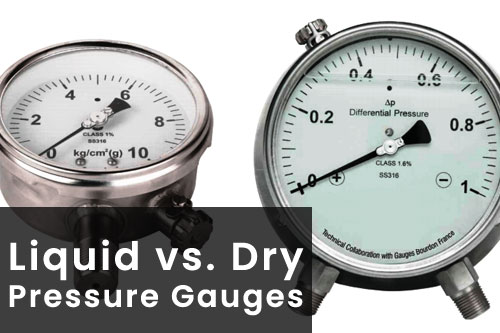

When should you use liquid-filled gauges?

Liquid-filled gauges are used to damp vibrations and pulsations and minimize their effect on the gauge dial pointer. They are used primarily in dynamic and rugged applications where sudden shocks or pressure spikes might occur. They help to ensure th...

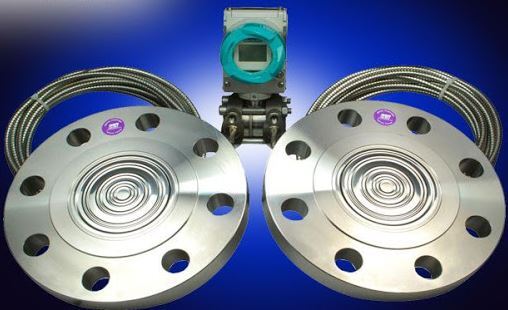

What Is Diaphragm Seals and How it works?

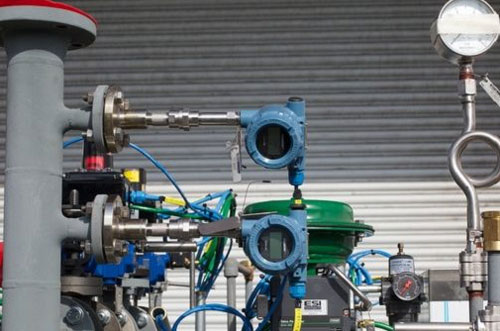

Diaphragm seals, also known as chemical seals or remote seals, are used for pressure measurements when the process medium should not come into contact with the pressurised parts of the measuring instrument. A diaphragm seal has two primary tasks:

...

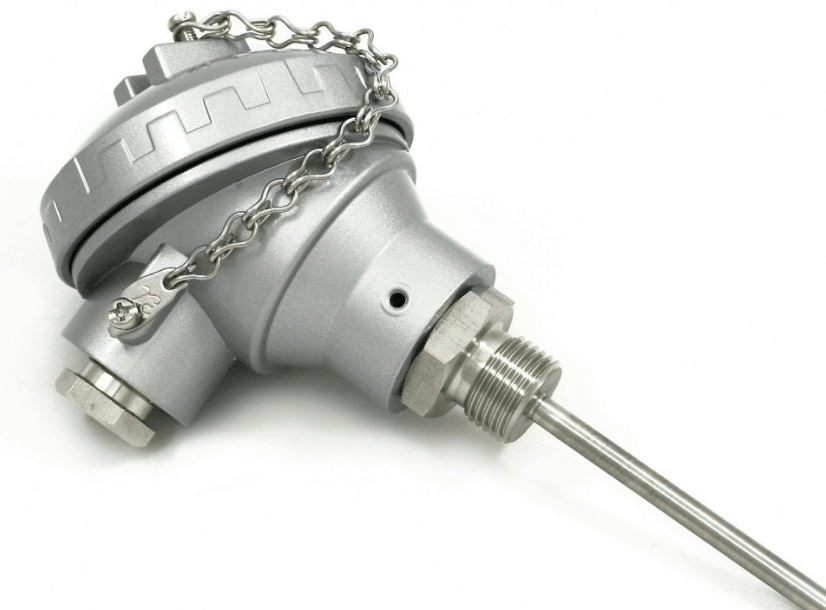

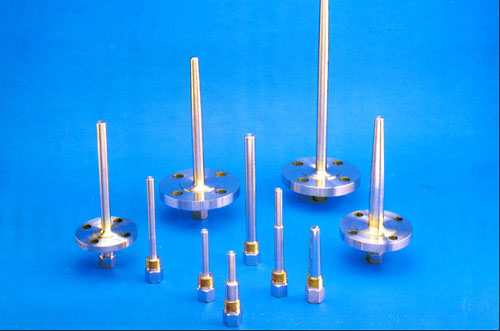

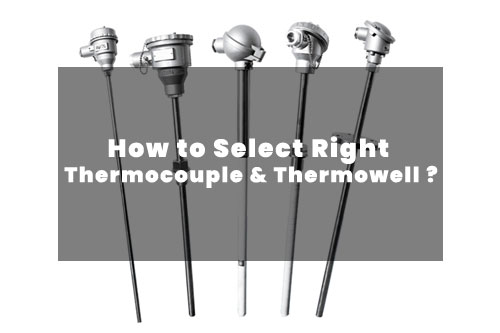

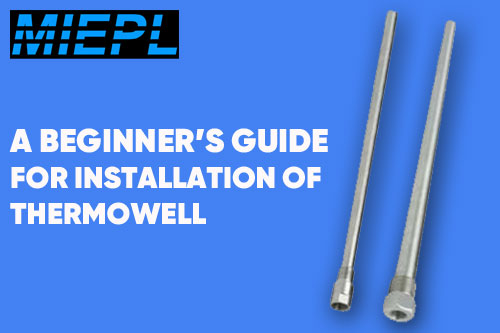

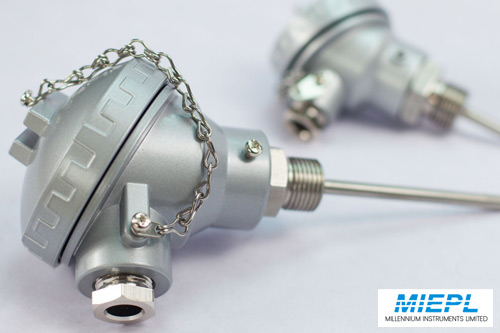

Thermowell Characteristics and Selection Criteria

Thermowells are used to guard temperature sensors such as thermocouples, thermistors and bimetal thermometers against damage from excessive pressure, material velocity and corrosion. They also increase the longevity of the sensor, allow sensor replac...

What role do valves play in plant safety?

The reliability of a valve is essential for the safety of the entire plant. Almost all pressure measuring instruments work in conjunction with a valve or a combination of valves. The choice of a high-quality valve is not only essential to ensure the ...

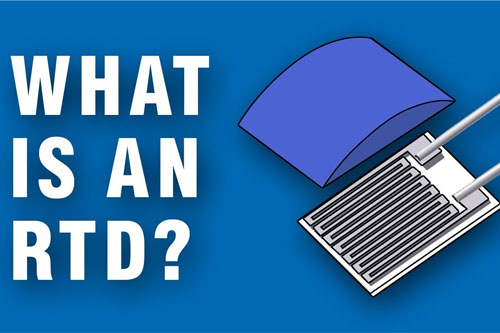

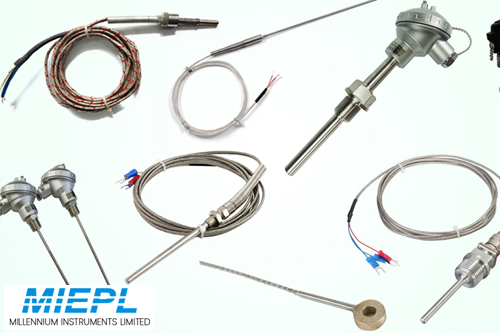

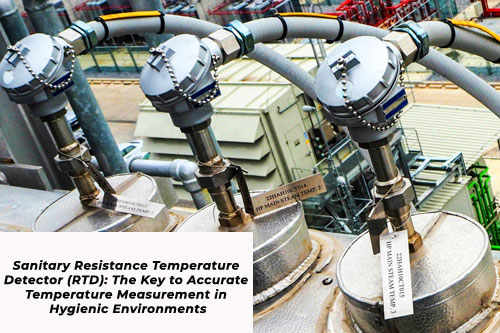

How Does an RTD Work?

"RTD" is an abbreviation for "Resistance Temperature Detector" An RTD is a type of temperature sensor which can be utilised in the manufacture of MIEPL' temperature probe range.

They are available with different temperature /...

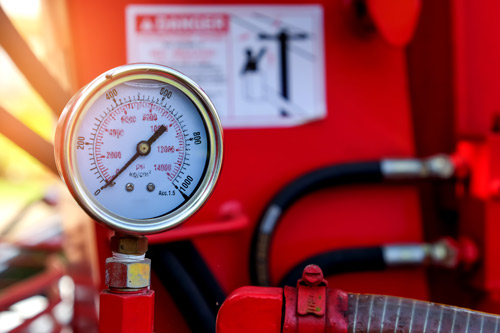

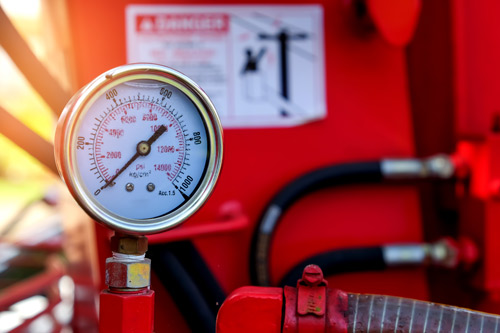

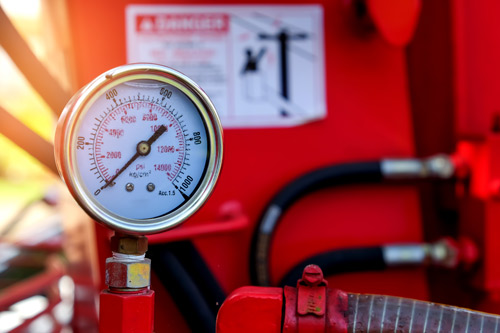

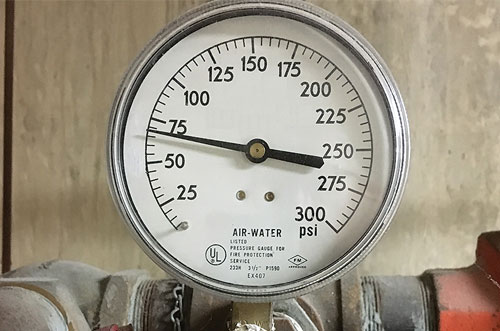

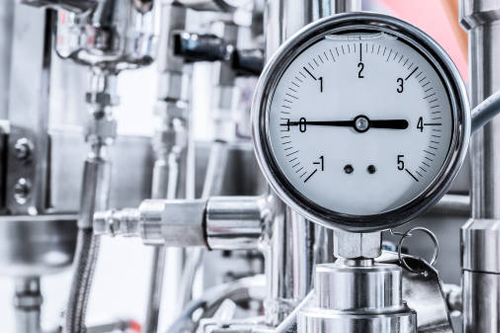

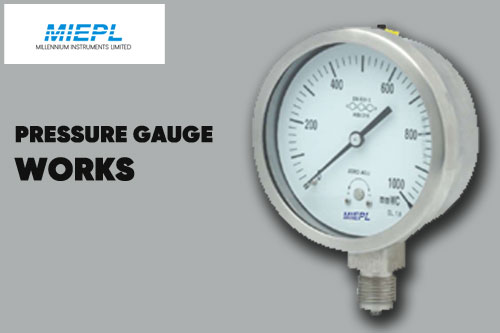

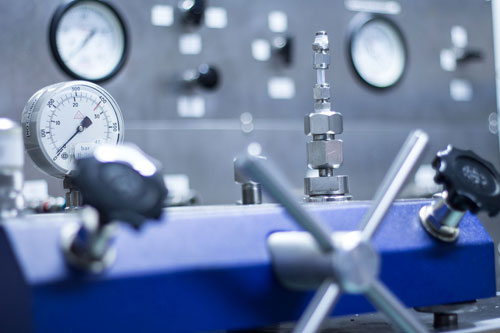

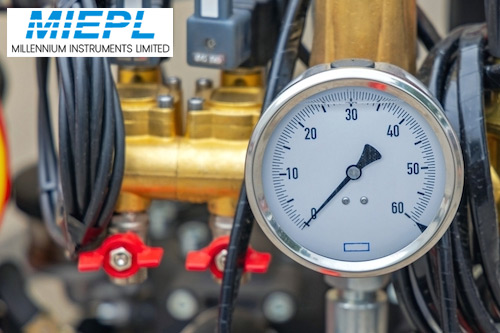

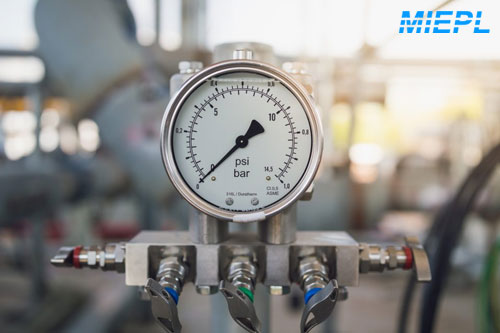

What is a pressure gauge?

A pressure gauge is a fluid intensity measurement device. Pressure gauges are required for the set-up and tuning of fluid power machines, and are indispensable in troubleshooting them. Without pressure gauges, fluid power systems would be both unpred...

solenoid valves...What are they?

Solenoid valves are electrically activated valves, typically used to control the flow or direction of air or liquid in fluid power systems. Used in both pneumatic and hydraulic fluid power functions, the spool or poppet design of most solenoid valves...

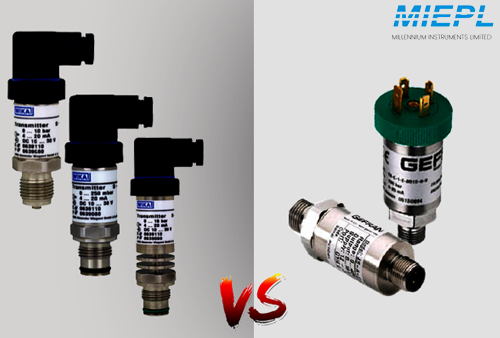

Pressure Transducer vs. Pressure Transmitter: Is There a Difference?

Almost everyone uses the terms “pressure transducer” and “pressure transmitter” interchangeably, but the two devices are technically not the same. A pressure transducer converts pressure to an electronic signal, while a pressure transmitter also ampl...

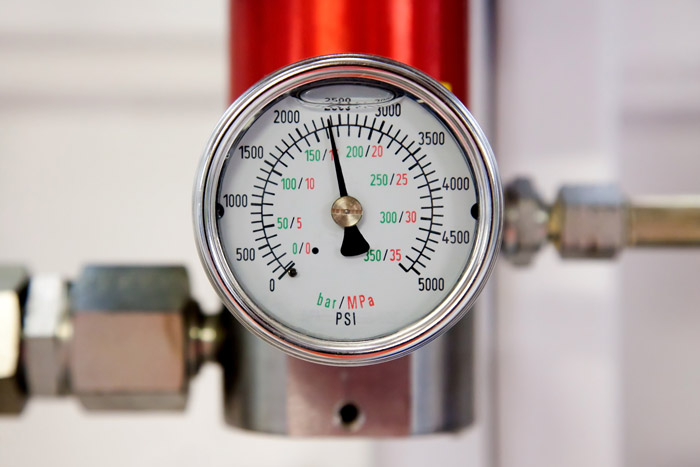

Basic Knowledge You Need to Know about Pressure Gauge

In industrial and commercial applications, pressure ranks only second to temperature as the most common process measurement. In fact, knowing the pressure often plays an important role in our daily life. Among the many kinds of pressure measurement d...

What you should consider about before purchase pressure switches?

Like many other process measuring instruments, there are many aspects you need to keep in mind before deciding to buy pressure switches however, below are the summary of general rules based on our decade’s experience, for you to follow up.

Basic...

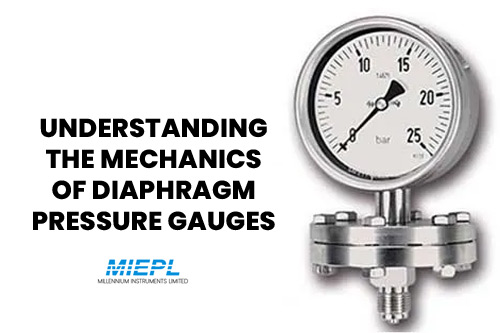

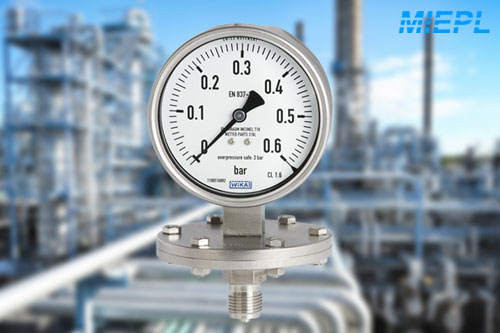

Things you need to know about Diaphragm pressure gauges

What is Diaphragm pressure gauges and when to use?

Diaphragm pressure gauges, also called sealgauges, are suitable for low pressure and overpressure measuring conditions.

Diaphragm pressure gauges are used to measure gases and liquids. They...

How do I select a proper seal for my application?

A few of the important parameters that one needs to consider while selecting a seal are system operating pressure, seal material compatibility with fluid and fluid operating temperature, resistance against extrusion, expected service life, ease of in...

How do you avoid seal failure?

“Seals are sometimes considered a commodity item by designers and engineers—a known quantity that doesn’t appear to require much thought,This can lead to a lack of care when it comes to training and/or tool selection, and that causes seals to become ...

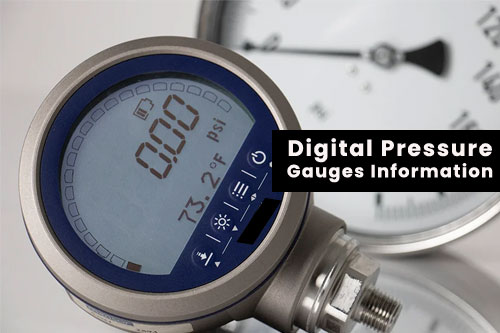

How to Choose the Best Digital Pressure Gauges

In most of the differential pressure measurement applications, various pressure gauges or sensors are used. These instruments are used primarily to convert the pressure differential into an electrical signal. Vapors, gases, suspensions, the density o...

RTD vs Thermocouple – What’s the difference?

What is the difference between and a resistance temperature detector (RTD) and a thermocouple? Both RTDs and thermocouples are sensors used to measure heat in scales such as Fahrenheit and Kelvin. Such devices are used in a broad range of application...

Which Pressure Switch is suitable for you?

Pressure switches are one of the most commonly used fluid control components. We use them at home, in our refrigerators, dishwashers and washing machines. Whenever we handle a gas or liquid we almost always need to control the pressure.

Our home...

What do you use for pressure transducer output?

Transducer Input / Output

An electrical input, called the excitation voltage, is required to operate a pressure transducer. This DC excitation can vary from 5-10VDC for unamplified transducers with millivolt output, to 8-36VDC for amplified tran...

Difference between RTD & Thermocouple

RTDs stands for ‘Resistance Temperature Detectors’ and they are generally referred to as ‘Resistance Thermometers’. RTD can be defined as a temperature sensor that operates on the measurement principle where the materials’ electrical resistance chang...

WHAT IS THERMOWELL? EXPLAIN THERMOWELL

This article is about WHAT IS THERMOWELL? EXPLAIN THERMOWELL and focusing to the engineers, technicians and supervisors. You will find lot of documents related to this article. Just navigate our websitewww.miepl.com

WHAT IS THERMOWELL? EXPLAIN T...

Types of RTDs, which one is the best one?

Resistance Temperature Detectors (RTDs) available today can generally be categorized into one of two basic types of RTDs, depending on how their temperature sensing element is constructed. One type of RTD contains thin-film elements and the other typ...

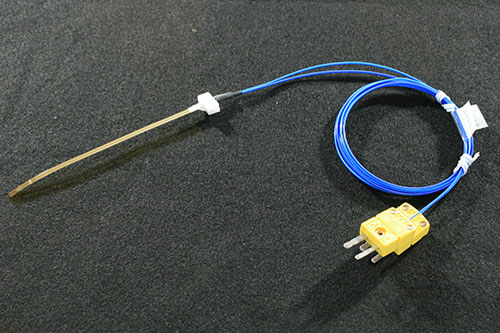

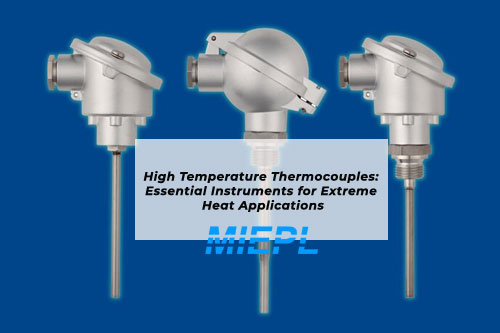

What Are The Most Common Applications for Thermocouples?

Thermocouples are the most widely used temperature sensors on the planet due to their combination of wide temperature capabilities, ruggedness, and low cost. Thermocouples are used in applications that range from home appliances to industrial process...

Common Techniques to Calibrate Thermocouples

Thermocouples are usually calibrated in one of three ways depending on the accuracy needed and the conditions where the calibration takes place.

The most accurate calibration is done in a laboratory using thermodynamic fixed points. This can be ...

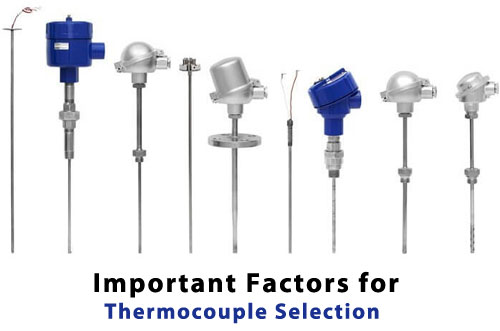

Thermocouple styles: probe, wire or surface?

Because a thermocouple can take many shapes and forms, it is important to understand how to correctly select the right sensor. The most commonly criteria used to make that choice are the temperature range, the chemical resistance, the abrasion and vi...

Temperature Effects on Pressure Gauges

Effects of Temperature

Changes in ambient temperature affect the accuracy of gauges in several ways. Range shift is caused by the change in modulus of elasticity of the bourdon. This effect increases proportionately as the pressure increases. As a g...

Pressure Gauges : Common Causes for Failures and Their Effective Solutions

Pressure or vacuum gauges, if get damaged or don’t function properly can lead to leaks and emissions which may result in contamination of workplace or in some cases a fire explosion. Such unfortunate incidents not only cost lives of those working wit...

How does an RTD sensor work and what RTD types are there?

RTD stands for Resistance Temperature Detector, which refers to a type of temperature sensor. As the name suggests, it uses changes in resistance to detect temperature, but that in itself might not tell you how an RTD works.

How does an RTD work...

Manometer calibration: when and how to do it?

A manometer is a tool to measure pressure in closed systems. Manometers measure different types of pressure, absolute, gauge, and differential. They

generally come in two types, liquid and elastic. These types in turn divide into several models:

...

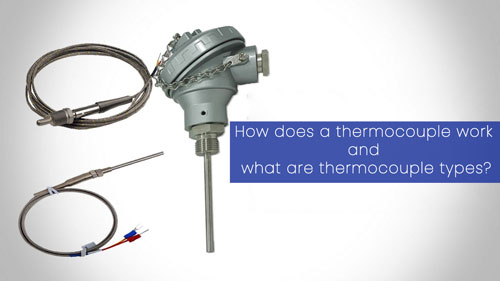

How does a thermocouple work and what are thermocouple types?

For many of us who work in automation, especially process automation, questions like what is a thermocouple, how does a thermocouple work, or what are the types of thermocouple can seem like very basic questions. Most of them will just say it’s a the...

How to calculate flow rate from pressure with a differential pressure transmitter?

Differential pressure transmitters (DP transmitters) are very versatile and can be used to measure more than pressure. In fact, over the years, they became go-to solutions for measuring level and flow. New, dedicated flow meters and level sensors are...

Why does water hammer affect pressure gauges and transmitters?

Water hammer is a high pressure surge or wave created by the kinetic energy of moving fluid when it is rapidly forced to stop or change direction, altering the liquid’s velocity. Rapid stopping or starting or changing of direction of an in compressib...

How Do Thermocouples Work? A Quick Tutorial

Thermocouples are electrical devices used to measure temperature. Their accuracy, rapid reaction time, and ability to withstand heavy vibrations, high pressure, and extreme temperatures make them ideal for a wide range of applications. But how does a...

How do diaphragm seals work?

Diaphragm seals, also known as chemical seals or remote seals, are used for pressure measurements when the process medium should not come into contact with the pressurised parts of the measuring instrument. A diaphragm seal has two primary tasks:

...

Pressure Switches vs Pressure Transmitters: What’s the Difference?

Many times the terms and definitions for pressure sensors such as switches, transducers and transmitters are used interchangeably with disregard to the actual meanings and differences. The exact definitions do differ from source to source spurring th...

Liquid-Filled vs. Dry Pressure Gauges: What's the difference?

There are two main types of pressure gauges. Today, we will go over why you might consider investing in a liquid filled gauge vs a dry one. Dry pressure gauges are the work horse of the industrial and commercial parts world. Look at most air compress...

How does a monoflange work?

Monoflanges combine the function of up to three valves in a particularly compact body, thanks to a precise network of internal passages and valve chambers. But what really happens inside a monoflange valve, once installed?

In a chemical process ...

What role do valves play in plant safety?

The reliability of a valve is essential for the safety of the entire plant. Almost all pressure measuring instruments work in conjunction with a valve or a combination of valves. The choice of a high-quality valve is not only essential to ensure the ...

How do you avoid seal failure?

“Seals are sometimes considered a commodity item by designers and engineers—a known quantity that doesn’t appear to require much thought,This can lead to a lack of care when it comes to training and/or tool selection, and that causes seals to become ...

How to Choose the Best Digital Pressure Gauges

The technology used in pressure gauges has been around for more than a century, and the pressure gauge is still one of the most common methods of measuring pressure today. The majority of pressure gauges still incorporate the Bourdon tube, socket and...

Mechanical vs digital or wireless pressure gauge

Mechanical pressure gauges are simple, cheap devices with local displays that show the pressure at a certain point in your process. This is one of the oldest forms of pressure measurement and it is still very common. Digital pressure gauges seek to b...

What new digital measurement tools can offer processing plants

As an aging workforce retires, new digital measurement tools offer plants a significant set of improvements.

Remember Scotty from Star Trek? He could always tell when the Enterprise’s engines were off by so much as a fraction of a hair, even whe...

4 potential solenoid valve failure modes and how to avoid them

Solenoid valves control critical systems like hydraulic or pneumatic actuators, emergency shutdown valves and high-integrity protection systems (HIPPS), but there is one thing they can’t control — the weather. While heat and humidity only make people...

7 Factors To Consider When Selecting Diaphragms

New class of integral piston diaphragms satisfies the demands that are critical in AODD pump operation As the parts that are constantly in motion during …

As the parts that are constantly in motion during the operation of an air-operated double-...

How does a thermocouple work and what are thermocouple types?

For many of us who work in automation, especially process automation, questions like what is a thermocouple, how does a thermocouple work, or what are the types of thermocouple can seem like very basic questions. Most of them will just say it’s a the...

The Most Important Things About Electric Contact Pressure Gauge

The SE model contact pressures with electric alarm contacts are suitable for controlling or regulating process sequences. The contact opens and closes electric circuits when it comes to the location of the pointer at the strain gauge. Our touch strai...

When to use a Diaphragm Seal ?

Process measurement sensors are not indestructible. Not even the most rugged device is fully immune to the chemical nature of process media or the kinetic impact associated with fluid composition and movement.

Balancing degrees of protection, us...

Why glycerin is used in pressure gauge?

Glycerin is the most commonly used liquid in liquid-filled gauges. Glycerin-filled gauges are a good value and provide good vibration dampening for applications at room temperature. These gauges work well in temperatures between -4 ° F and + 140 ° F ...

Advantages & Disadvantages of thermocouple

Advantages of Thermocouple:

They are capable of being used to directly measure temperatures up to 2600ºC; and

The junction of the thermocouple can be grounded and brought into direct contact with the measured material.

Disadvantages of t...

What is an RTD ? How RTD works ? Advantages and Disadvantages of RTD?

RTD

Resistance Temperature detectors (RTDs) are sensors used to measure temperature.

Generally greater stability,accuracy and repeatability when compared to thermocouples.

Slowly becoming the proffered temperature measurement device in many indust...

WHAT ARE LIQUID FILLED TEMPERATURE GAUGES?

The liquid filled temperature gauges are most often used temperature gauges in industries. In this type liquid is filled in the metal tube. most generally used liquids are mercury and alcohol.

OPERATION PRINCIPLE OF LIQUID FILLED TEMPERATURE GAU...

WHAT YOU SHOULD CONSIDER ABOUT BEFORE PURCHASE PRESSURE SWITCHES?

Like many other process measuring instruments, there are many aspects you need to keep in mind before deciding to buy pressure switches however, below are the summary of general rules based on our decade’s experience, for you to follow up.

Basic...

WHICH PRESSURE SWITCH IS SUITABLE FOR YOU?

Pressure switches are one of the most commonly used fluid control components. We use them at home, in our refrigerators, dishwashers and washing machines. Whenever we handle a gas or liquid we almost always need to control the pressure.

Our home...

Difference between wire wound & film RTD’s

Introduction

An RTD is a device which contains an electrical resistance source (referred to as a “sensing element” or “bulb”) which changes resistance value depending on it’s temperature. This change of resistance with temperature can be measured an...

COMMON TECHNIQUES TO CALIBRATE THERMOCOUPLES

Thermocouples are usually calibrated in one of three ways depending on the accuracy needed and the conditions where the calibration takes place.

The most accurate calibration is done in a laboratory using thermodynamic fixed points. This can be ...

When to use a Diaphragm Seal?

Process measurement sensors are not indestructible. Not even the most rugged device is fully immune to the chemical nature of process media or the kinetic impact associated with fluid composition and movement.

Balancing degrees of protection, us...

What is Hammer Effect in Gauges ?

Today we will be looking at the kind of hammer effect that impacts industrial fluid applications.

The hammer effect (or water hammer) can harm valves, pipes, and gauges in any water, oil, or gas application. It occurs when the liquid pressure is...

7 Factors To Consider When Selecting Diaphragms

New class of integral piston diaphragms satisfies the demands that are critical in AODD pump operation As the parts that are constantly in motion during …

As the parts that are constantly in motion during the operation of an air-operated double-...

How to Choose the Best Digital Pressure Gauges

The technology used in pressure gauges has been around for more than a century, and the pressure gauge is still one of the most common methods of measuring pressure today. The majority of pressure gauges still incorporate the Bourdon tube, socket and...

How do I select a proper seal for my application?

A few of the important parameters that one needs to consider while selecting a seal are system operating pressure, seal material compatibility with fluid and fluid operating temperature, resistance against extrusion, expected service life, ease of in...

How does a monoflange work?

Monoflanges combine the function of up to three valves in a particularly compact body, thanks to a precise network of internal passages and valve chambers. But what really happens inside a monoflange valve, once installed?

In a chemical process ...

Basic Knowledge You Need to Know about Pressure Gauge

In industrial and commercial applications, pressure ranks only second to temperature as the most common process measurement. In fact, knowing the pressure often plays an important role in our daily life. Among the many kinds of pressure measurement d...

What do you use for pressure transducer output?

Transducer Input / Output

An electrical input, called the excitation voltage, is required to operate a pressure transducer. This DC excitation can vary from 5-10VDC for unamplified transducers with millivolt output, to 8-36VDC for amplified transduc...

Why does water hammer affect pressure gauges and transmitters?

Water hammer is a high pressure surge or wave created by the kinetic energy of moving fluid when it is rapidly forced to stop or change direction, altering the liquid’s velocity. Rapid stopping or starting or changing of direction of an in compressib...

What role do valves play in plant safety?

The reliability of a valve is essential for the safety of the entire plant. Almost all pressure measuring instruments work in conjunction with a valve or a combination of valves. The choice of a high-quality valve is not only essential to ensure the ...

Common Types of Diaphragm Seals

Diaphragm seals are commonly categorized according to their process connection. The type of connection used must be determined based on the intended application. Please take the time to learn more about a few common types of seals.

Threaded

Thr...

How to Select Fill Fluids For Diaphragm Seals

Making the right diaphragm seal fill fluid selection is important. You understand your process and parameters well, but having a partner to assist you is always helpful. ESP will supply detailed data to help inform your decision regarding the type of...

Winery Industry: Pressure Gauges and Diaphragm Seals

Truly exceptional wine cannot be rushed. Making it, however, involves more than just time. At all stages of production, careful monitoring and testing are essential. Fortunately, MIEPL has the reliable instruments you need to make sure your wine is o...

Why Choose MIEPL for Your Diaphragm Seals?

MIEPL is the perfect choice when you need to purchase diaphragm seals. We understand that availability is a major consideration when purchasing seals, and are proud to say that we ship dry Bourdon diaphragm seals within 2 days, for your convenience. ...

Industry Overview: Oil and Gas

The oil and gas industry creates a variety of challenges. Whether your need is for upstream oil and gas, transportation, or downstream, MIEPL offers products that fit your process and safety needs. Things to consider when selecting products for the o...

What are Capillaries?

There are many reasons to think about using capillaries with diaphragm seals. Before considering them, it’s important to understand the role that a capillary plays. Capillaries are used for mounting pressure gauges, transmitters, and switches away fr...

Static pressure vs total pressure vs dynamic pressure

Pressure transmitters usually measure two pressure values: static pressure and dynamic pressure. However, there are actually three. This article delves into the three types of pressure in detail.

Types of pressure

Static pressure

Static pr...

Why glycerin is used in pressure gauge?

Glycerin is the most commonly used liquid in liquid-filled gauges. Glycerin-filled gauges are a good value and provide good vibration dampening for applications at room temperature. These gauges work well in temperatures between -4 ° F and + 140 ° F ...

When to Select a Liquid VS Dry Pressure Gauge

When it comes to choosing a pressure gauge, the decision might seem simple. Liquid filled or dry. But before jumping to a decision, there are some factors to determine which gauge is the right fit for you and your application.

Being informed abo...

Did you Vent your Pressure Gauge?

Better yet, do you need to? If you have a dry gauge, don't panic! Venting is strictly for liquid filled gauges. As discussed in When to Select a Liquid VS Dry Pressure Gauge, there are many advantages to a liquid gauge when used correctly in specific...

Pressure Gauges : Common Causes for Failures and Their Effective Solutions

Pressure or vacuum gauges, if get damaged or don’t function properly can lead to leaks and emissions which may result in contamination of workplace or in some cases a fire explosion. Such unfortunate incidents not only cost lives of those working wit...

Pressure Gauge Selection at Miepl

Mechanical pressure gauges, which require no external power, provide an affordable and reliable source of accurate pressure measurement. The need to select the right pressure gauge requires that the device be accurately specified otherwise numerous p...

Pressure Gauge Accessories at MIEPL

The following are the Pressure Gauge Accessories:

Snubber

Pigtail Syphon

U Syphon

Gauge saver

Gauge Adaptor

Gauge Union

Pressure Gauge Accessories

Snubber

The Snubber (Pulsation Dampener) protects the pressure ins...

How To Select a Suitable Thermowell

In many pressurised processes it is often not possible or advisable to insert the temperature instrument directly into the media being measured. A thermowell protects the temperature instrument, permits the instrument to be exchanged or calibrated, a...

Some of the Most Common Applications for Thermocouples?

Thermocouples are the most widely used temperature sensors on the planet due to their combination of wide temperature capabilities, ruggedness, and low cost. Thermocouples are used in applications that range from home appliances to industrial process...

WATER HAMMER: DANGERS AND TIPS TO PREVENT IT FROM HAPPENING

Recently, one personal care plant reached out to MIEPL for help after a recorded safety incident caused by water hammer. After a swing check valve was forced shut rapidly by product moving through the pipeline, the piping was jarred from its supports...

Pressure Gauges: Made to Measure

Pressure and flow readings provide a means of assessing the performance of hydraulic and pneumatic systems and aid troubleshooting when malfunctions occur.

The majority of gauges for measuring pressure have one characteristic in common: the pres...

Which Pressure Switch is suitable for you?

Pressure switches are one of the most commonly used fluid control components. We use them at home, in our refrigerators, dishwashers and washing machines. Whenever we handle a gas or liquid we almost always need to control the pressure.

Our home...

Pressure gauges: The unsung heroes of Industry

Knowing which style of pressure gauge is right for your fluid power system is critical in ensuring consistent, efficient operation.

Pressure gauges are unsung heroes in many hydraulic systems. They are neither directing flow nor controlling pres...

Temperature Measurement by Thermowell

Definition of Thermowell

A thermowell is a pressure tight receptacle designed to accept a temperature sensing element and provide a means to insert that element into a vessel or pipe.

The American Society for Testing and Materials (ASTM) has de...

Thermowell Types and Tips for Their Selection

Temperature sensors are extensively used across various industries for temperature measurements. These devices are regularly subjected to high pressure, corrosive environments, material velocity, etc. Regular exposure to these environments may damage...

Know Three Interesting Uses of Pressure Transmitters

Pressure transmitters are used to measure the pressure of liquids, fluids, and gases in the process industry. Also, known as pressure transducers, these equipment do more than just checking the pressure of the working equipment. Over the years, proce...

Absolute and Gauge Pressure Transmitters - Overview and Working Principle

Over the years, pressure transmitters are utilized to measure liquid levels of open or pressurized tanks in industrial processes. With rapid digitalization, these transmitters now comprise advanced technology and improved additional features. This ad...

What is a Thermocouple and How Does It Work?

A thermocouple sensor is one of the many types of temperature sensing devices used in measuring different variables in industry applications. They are often used for temperature measurement and control at gas turbine exhausts, diesel engines, high-te...

The secret to smart Automation instrument success

In this installment of Automation Zone, new capabilities wow and amaze, but can your team take advantage of them?

Process instruments have been digital (smart) for many years. In fact, microprocessor-based measuring devices for flow, level, pres...

What is Industrial Automation?

Industrial automation is the use of control systems, such as computers or robots, and information technologies for handling different processes and machineries in an industry to replace a human being. It is the second step beyond mechanization in the...

8 reasons to choose a pressure instrument with a ceramic measuring cell

Pressure measurement is one of the oldest, most common means of process control: It is tried, tested and proven with good reason. Pressure technology is versatile because it can measure level, density and interface, and users can choose a measuring c...

Why differential pressure gauges?

How differential pressure gauges influence the success of process control applications with many measurement variables.

In the world of process control there are many measurement variables, generally falling under the categories of pressure, tem...

Important Factors for Thermocouple Selection

It would be difficult to chart a career course in the industrial process control field without being exposed to thermocouples. They are the ubiquitous basic temperature measuring tools with which all process engineers and operators should be familiar...

Vacuum Gauges Working Principle at Miepl

Vacuum Gauges where the Pressure Readings are Independent of the Type of Gas (Mechanical Vacuum Gauges)

Bourdon Vacuum Gauge

The inside of a tube which is bent into a circular arc (the so-called Bourdon tube) is connected to the vacuum system. ...

General Specification of Thermowells

Here we shall see detailed specifications of Thermowells.

Thermowells shall be provided with every temperature element and shall be machined out of bar stock up to length 600mm and with SS 316 material as a minimum.

Thermowell Specification...

Pressure and Temperature Gauges

PRESSURE GAUGES

Bourdon tube pressure gauge

Diaphragm pressure gauge

Capsule pressure gauge

Bourdon tube pressure gauge with chemical seal

Differential pressure gauge

Absolute pressure gauge with diaphragm

TEMPERATURE GAUGES

...

What is RTD Sensor and How Does it Work?

RTD or resistive temperature detector is a probe or a device used to measure and control temperature across industrial applications. A resistor changes its value based on the change on temperature. So, the temperature measurement is relative and not ...

Mechanical vs digital or wireless pressure gauge

Mechanical pressure gauges are simple, cheap devices with local displays that show the pressure at a certain point in your process. This is one of the oldest forms of pressure measurement and it is still very common. Digital pressure gauges seek to b...

Selecting pressure gauges: New advances on an old technology

Pressure gauges are still useful in many applications, and developments can extend their capabilities.

While mechanical pressure gauges have been mainstays in the process industry, they have also brought some challenges with them. Still, when a ...

How to select hydraulic pressure gauge ranges

Specifying a standard hydraulic pressure gauge range makes life so much easier.

We thought we understood it but even now still struggle every time somebody tells us the range specified is not available.

Our Micropac pumps are used on pr...

Proper instrumentation is key to profitable plunger lift applications

Gas flow and pressure spikes caused by using a plunger to clear the well bore create challenges for wellhead instrumentation.

The current low price of natural gas puts increased pressure on producers to be as efficient and cost-effective as poss...

Complying with Changes to the Pressure Equipment Directive

By HPi Verification Services Despite being synonymous with regulation and stringent HSE policies, many global oil and gas companies, particularly those entering the industry in …

Despite being synonymous with regulation and stringent HSE policie...

How to Choose Diaphragm Seals for Your Application?

Transmitters, switches, and pressure gauges find application in various process applications across the world. Although they are designed to withstand abusive work environments, sometimes they may fail due to various reasons. To avoid this, these dia...

The lowdown on gauges

What is a gauge? A gauge is any device designed to measure the intensity of a particular type of energy or quality. A light meter is a device that converts photon energy into electrical current so it can measure the intensity of light, for example. G...

When to Select a Liquid VS Dry Pressure Gauge

When it comes to choosing a pressure gauge, the decision might seem simple. Liquid filled or dry. But before jumping to a decision, there are some factors to determine which gauge is the right fit for you and your application.

Being informed abo...

THREE CRITICAL FACTORS THAT AFFECT THE PERFORMANCE OF YOUR PRESSURE GAUGE

Pressure gauges are an integral part of numerous industries, but often do not get as much attention as required. Industries like brewing, refining, etc., cannot function without pressure gauges and importance must be placed on pressure gauge calibrat...

8 COMMON CAUSES OF PRESSURE GAUGE FAILURE

Pressure gauges indicate if a system or component in a process is operating correctly or not. They are extremely critical and generally require little to no maintenance other than the periodic pressure gauge calibration.

However, it is normal fo...

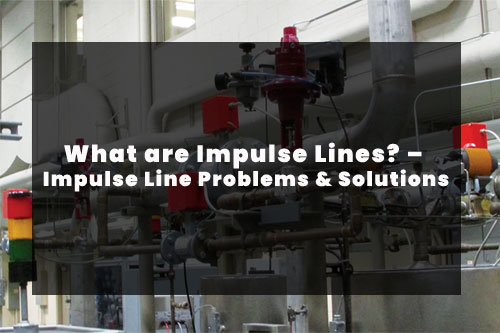

What are Impulse Lines? – Impulse Line Problems & Solutions

Taking a DP, gauge, or absolute pressure reading from a process involves creating process connections so the pressure can reach the sensor.

Impulse Line

The impulse line carries the process pressure from the tapping point to the transmitter...

Pressure Gauge Snubbers

A pressure gauge snubber is a device used to suppress (“snub”) excess force or rapid movement in mechanical systems. Pressure snubbers are designed to dampen the effect of pressure pulses and spikes to assure longer service life and readability of pr...

Instrument Protection Methods: Seals

Here we shall see recommended practices for the protection of the instrument from harsh process conditions. In this article, we shall learn about Diaphragm seal and liquid seal methods to protect the instrument.

A seal can be a mechanical isolat...

Filling liquids in pressure gauges: Usage and advantages

Liquid-filled pressure gauges are used in applications that involve high dynamic shock and vibration loading. The filling liquid dampens the vibrations that occur and thus takes the load off the mechanical components of the pressure gauge.

Use o...

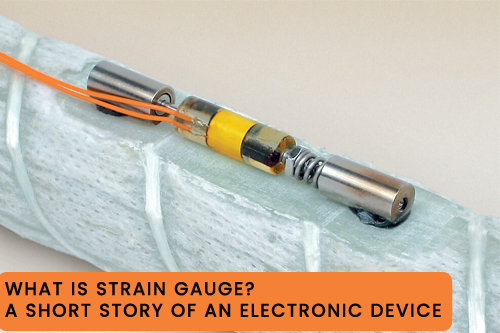

What Is Strain Gauge? A Short Story of An Electronic Device

Welcome to Miepl Blog. Today and in this article, we are going to have a look at the question “What Is Strain Gauge ?” Strain gauges are exceptionally useful measurement tools, often because of their sensitivity. As evidence, strain gages are typical...

A Complete Answer To What Is A Pressure Gauge

The measurement of pressure is crucial to the safe and proper functioning of many types of industrial systems and corresponding industrial products. Entire fluid power systems would be unpredictable and unreliable without an accurate way to measure a...

Pressure Gauge Problems

Long before there were pressure transmitters, there were mechanical pressure gauges.

The concept of a curved Bourdon tube dates back to the mid 19th century and there are devices available today little removed from that time.

Gauges operate...

What’s the problem with shock and vibration ?

Shock and vibration are among the worst enemies of any pressure sensor. They are also the hardest to identify, and even then it can be very difficult to rectify the problem and avoid breakages. Remember: a pressure sensor is a highly sensitive and ac...

Vacuum Gauges Working Principle

Vacuum Gauges where the Pressure Readings are Independent of the Type of Gas (Mechanical Vacuum Gauges)

Bourdon Vacuum Gauge

The inside of a tube which is bent into a circular arc (the so-called Bourdon tube) is connected to the vacuum system. ...

Eight reasons to choose a pressure instrument with a ceramic measuring cell

Pressure measurement is one of the oldest, most common means of process control. Users can choose a measuring cell material that best suits their processes depending on their requirements. The most popular cell material is metal, but ceramic is emerg...

6 Tips to Help You Install the Pressure Gauge Perfectly

Is your pressure gauge installed properly? Incorrect installation of the pressure gauge can cause premature failure of the gauge and prevent you from troubleshooting problems in the equipment or process. Don’t let this happen in your factory. Use the...

How Does a Differential Pressure Gauge Work

Differential pressure gauges are widely used in the industrial field, and they are usually good solutions to some problems. Many friends are curious about how does a differential pressure gauge work. In fact, knowing the working principle of a differ...

Why RTD installed after the Orifice Plate ?

The location of the RTD (thermowell), positioned downstream of the orifice plate so the turbulence it generates will not create additional turbulence at the orifice plate. The American Gas Association (AGA) allows for upstream placement of the thermo...

What is a Thermopile ?

A thermopile is an electronic device that converts thermal energy into electrical energy. It is composed of several thermocouples connected usually in series or, less commonly, in parallel.

Thermocouples operate by measuring the temperature diff...

Pressure Gauges: Liquid-Filled vs. Dry Pressure Gauges

WHAT’S THE DIFFERENCE BETWEEN LIQUID-FILLED AND DRY PRESSURE GAUGES?

Most pressure gauges you find will be a dry pressure gauge, mostly seen on items like bicycle pumps, compressors, air and gas regulators, and more. A dry pressure gauge is affordab...

HOW COMPOUND PRESSURE GAUGE WORKS

When selecting a pressure transducer, or a digital pressure gauge, it is important to understand pressure types, and how they perform under different circumstances.

We have already given an overview of each pressure type, and covered absolute an...

How to select proper diaphragm materials

Air-operated double-diaphragm (AODD) pumps have grown into workhorses in many diverse industries, but they will only perform properly if compatible diaphragms are used.

Compatibility in any relationship, from marriage to roommate and rock group ...

When and when not to use thermowells in process temperature measurement

Thermowells can be a design and maintenance headache, but recent innovations reduce some long-standing problems, and alternative measuring technologies can eliminate them entirely. Which approach is best for you?

Within the world of process inst...

How to Select Right Thermocouple & Thermowell ?

To select an ideal thermocouple first we need to understand the need of measurement application and requirement.

Factors affecting temperature change

Accuracy required- impact of sensor accuracy on overall measurement accuracy.

Length of d...

What to Choose RTD or Thermocouple ?

Thermocouples (TCs) and resistance temperature detectors (RTDs) are the most widely used temperature sensors in automation and process control. They are found embedded in motors, valves, turbines, bearings, and a host of other devices. Most smart ins...

Flexibility And Usefulness Of Thermocouples As Sensors Explained

There are a variety of sensors such as RTDs and thermocouples that are used for thermal control and temperature measurement across industries. Maintaining a certain temperature range is crucial for many processes due to the sensitivity of the materia...

Why Use Platinum In RTD Temperature Sensors?

Resistance temperature detectors (RTDs) are one of the more popular temperature sensors, and are also known as resistance thermometers. These temperature sensors work on the principle of resistance-temperature interrelation. The RTDs feature a pure m...

Hydraulic vs Pneumatic Pressure in Calibration

There is a lot to think about when deciding how to design or augment a calibration program. Especially when dealing with a wide variety of pressure ranges - both high and low - where gas and liquid are being used in the process and as the medium for ...

The Many Types of Pressure Gauges in Measurement Industry

A gauge is essentially an instrument or device for measuring the magnitude, amount, or contents of something, typically with an analog or digital display. This can be a measurement of any property like pressure, flow, temperature, fuel, or length. Th...

Know All About Resistance Based Temperature Sensors – RTDs

Sensors are an integral part of several electronic and electromechanical devices, equipment and machinery across industries. Temperature and pressure monitoring is required in several manufacturing processes. Certain temperature and pressure ranges n...

Surface-Mount RTDs: Introduction, Configurations & Applications

A resistance temperature detector (RTD) is a type of temperature sensor that measures temperature by sensing the change in resistance on the surface. These RTD sensors are small, have quick response times, and offer high-temperature sensitivity. Owin...

7 BASIC TYPES OF TEMPERATURE MEASURING SENSORS

Temperature is defined as the energy level of matter which can be evidenced by some change in that matter. Temperature measuring sensors come in a wide variety and have one thing in common: they all measure temperature by sensing some change in a phy...

What Is Strain Gauge? A Short Story of An Electronic Device

Welcome to MIEPL Blog. Today and in this article, we are going to have a look at the question “What Is Strain Gauge ?” Strain gauges are exceptionally useful measurement tools, often because of their sensitivity. As evidence, strain gages are typical...

A Complete Answer To What Is A Pressure Gauge

The measurement of pressure is crucial to the safe and proper functioning of many types of industrial systems and corresponding industrial products. Entire fluid power systems would be unpredictable and unreliable without an accurate way to measure a...

Troubleshooting Pressure Gauges and Impulse Lines

Automation professionals are confronted every day with obstacles caused by outdated instrumentation technologies and practices. When first installed, these solutions were likely state-of-the-art and improved existing installations, but many have now ...

Common Techniques to Calibrate Thermocouples

Thermocouples are usually calibrated in one of three ways depending on the accuracy needed and the conditions where the calibration takes place.

The most accurate calibration is done in a laboratory using thermodynamic fixed points. This can be ...

Determining calibration error of Bourdon tube pressure gauge

How do you calculate maximum gauge error in pressure measurement with a bourdon gauge instrument?

The cardinal point or division markings on the dial face of a Bourdon tube pressure gauge can be separated by a large amount making it difficult to...

Protect sensing instruments with diaphragm seals

Replacing aging or broken sensing equipment is one of the major challenges users face with their pressure measurement. Whether it’s a pressure gauge, pressure transducer, pressure switch, or a pressure transmitter, many users find that they require r...

What are the Challenges of Low Pressure Calibration?

Calibration of Instruments is important in monitoring pressure readings accurately. This can be tough, especially in environments where working conditions require low-pressure (.2 to 5 PSI) measurement, such as in medical instrumentation, environment...

Thermowells & types of thermowells,

Thermowells are typically constructed of solid drilled-out bar stock and are designed to protect a temperature sensor from the flow, high pressure and harsh environments. A thermowell has the added advantages of allowing the removal or replacement of...

What is a platinum resistance thermometer?

Using resistance to measure temperature

A platinum resistance thermometer (PRT) is a piece of platinum wire which determines the temperature by measuring its electrical resistance. It is referred to as a temperature sensor. When manufactured careful...

'Bourdon Original' by Baumer: A historical innovation

While the wheel of innovation turns faster and faster in the process industry, a more than 160-year-old technology is still used for pressure measurement today. The 'Bourdon tube' developed by Eugène Bourdon in 1849 and named after him is still the m...

Vacuum pressure gauges - How they work

A vacuum gauge measures pressure below the atmospheric pressure. Normally the atmospheric pressure is set as zero and the vacuum pressure is given in negative values, so -1 barg (-15 psig) means complete vacuum.

What is vacuum pressure?

The atm...

Instrument Protection Methods: Seals

Here we shall see recommended practices for the protection of the instrument from harsh process conditions. In this article, we shall learn about Diaphragm seal and liquid seal methods to protect the instrument.

A seal can be a mechanical isolat...

Diaphragm Seal Material Selection

For Material selection our basis is Pipe material specs .

The material , pipe is made up of is surely compatible with process fluid so it must work with our instruments also. BUT THIS NOT THE CASE ALWAYS !

AND why this new thing to check wi...

Reasons for Choosing a Liquid-Filled Industrial Pressure Gauge

Liquid-filled gauges surpass dry gauges for two main reasons: performance and extended service life. Pressure gauges that are filled with a liquid, usually glycerin or silicone oil, perform better in less-than-ideal conditions. They are also more eco...

What is an RTD?

Platinum Resistance Temperature Detectors (Pt-RTDs) are temperature sensors that have a positive, predictable and nearly linear change in resistance when subjected to a corresponding change in their body temperature.

Depositing a thin Platinum f...

Eight reasons to choose a pressure instrument with a ceramic measuring cell

Pressure measurement is one of the oldest, most common means of process control. Users can choose a measuring cell material that best suits their processes depending on their requirements. The most popular cell material is metal, but ceramic is emerg...

How Does a Differential Pressure Gauge Work

Differential pressure gauges are widely used in the industrial field, and they are usually good solutions to some problems. Many friends are curious about how does a differential pressure gauge work. In fact, knowing the working principle of a differ...

Tips on Looking Out For the Best Temperature Gauge

A gauge, as specified by its various definitions, can mean a lot of things to diverse users. In order to regulate its exact meaning, you will have to first see at the framework where this word is being used. Temperature gauge is a device that shows t...

HOW TO CALIBRATE A TEMPERATURE GAUGE

Calibrating temperature gauges used in your process is extremely important and ensures that your devices measure accurate temperatures at all times. At MIEPL, we supply a range of temperature gauges spanning across several different sizes and immersi...

Analog vs Digital Pressure Gauges

Analog pressure gauges have a long history of providing quick, reliable pressure readings, but the popularity of digital gauges is on the rise. Here’s why.

A Brief Overview of Pressure Gauges

Put simply, a pressure gauge is a tool that provides...

How to Calibrate a Thermocouple

A thermocouple can be any junction between two different metals and may be used to measure temperature. Each metal produces a different electrical potential that varies according to changes in temperature. This rate of change is different for each of...

What is the working principle of bimetal thermometer?

Bimetal thermometer is a kind of instrument which can directly measure the middle and low temperature of a medium. Its working principle is based on the principle of solid thermal expansion, and two pieces of metal sheets with great difference in exp...

How to inspect thermowell of bimetal thermometer?

The thermowell of bimetallic thermometer is set outside the temperature measuring element, and can also be installed in advance on the device with pressure which is inconvenient to disassemble. It can resist the pressure and corrosion of the measurin...

Analog vs. Digital Pressure Gauges: Which One Is Right for You?

Pressure gauges are essential tools in industrial processes and applications. With the development of digital pressure gauges, people are shifting away from manual analog ones, even though they provide quick and reliable readings.

However, they ...

Understanding the Different Types of Mud Gauges

Whether drilling on land or in an offshore drilling rig, you want something that observes and monitors the pressure and allows the driller or operator to observe pressure while working on drilling or offshore oil rigs.

If you want to learn more ...

Strain Gauge: Working Principle & Diagram

A strain gauge is a resistor used to measure strain on an object. When an external force is applied on an object, due to which there is a deformation occurs in the shape of the object. This deformation in the shape is both compressive or tensile is c...

Thermocouple vs. Thermopile: A Complete Comparison & Advantages of Each Type

Why is the comparison between Thermocouple vs. Thermopile too important? The main difference between Thermocouple and Thermopile is their method of measurement. The thermocouple is a thermoelectric instrument, while the thermopile is an instrument th...

Why Are Pressure Gauges Important For Industrial Operations?

Your car’s tire will burst if you fill it with too much air. To avoid that, you use a pressure gauge to know when to stop pumping air.

Similarly, your industrial machines can also get damaged if you don’t keep an eye on the pressure. This is why...

3 Different Types of Pressure Gauges Used in Drilling Industry

Asking someone how many types of pressure gauges there are is only half a question. It can be said that there are two types of pressure gauges, analog and digital. In fact, pressure gauges can also be classified based on the working principle. Simila...

Why should I use a thermocouple with a transmitter?

A temperature sensor is a device that provides temperature measurement via an electrical signal.

When there is a change in temperature, a thermocouple will change its voltage and an RTD will change its resistance in proportion to the change in t...

What Is a Pressure Gauge and When Do You Need One?

In some occurrences, knowing the force of pressure is important to the function of whatever process is in need of this quantification.

For most people, pressure starts and ends as a headache. However, that’s not really what pressure is or means....

Thermocouple Calibration

Calibration is the process of determining or adjusting the deviation of a instrument (which is under calibration) with reference to a said standard. This is done by comparing the device or the output of an instrument to a standard having known charac...

WHAT IS A THERMOWELL?

Process control environments can be pretty inhospitable at times; fluids and gases can be corrosive and variables like temperature and pressure can reach extreme valuations. Even a moderately harsh environment can be detrimental to equipment if it is...

Difference Between Gauge and Absolute Pressure Measurement

Pressure can be described as the force applied to an area. There are many different systems of pressure measurement, with absolute pressure and sealed gauge pressure being two of the most common. There are many differences between these two measureme...

What Is a Manometer?

A manometer may be any device that measures pressure. However, unless otherwise qualified, the term “manometer” most often refers specifically to a U-shaped tube partly filled with fluid. You can easily build this type of manometer as part of a labor...

Why Are Pressure Gauges Liquid Filled

So you’ve figured out what size dial and connection you need on the gauge for your application. You even know your preference on wetted materials. But what about having the gauge dry vs. liquid filled? What are the benefits to a liquid filled gauge? ...

THE DIFFERENCE BETWEEN GLYCERINE FILLED PRESSURE GAUGE AND SILICONE FILLED PRESSURE GAUGE

As we all know, vibration, pulsation, and pressure peaks are the most common reasons for pressure gauge performance degradation and failure. In today’s more demanding environment, instruments in the oil, natural gas, and chemical industries and proce...

How Do You Tell a Thermocouple From an RTD?

Some thermocouples look very similar to an RTD. There are, however, usually some small differences. You usually can’t just replace a thermocouple with an RTD without making some changes, such as, reprogramming the controller for a different type of t...

Thermocouple Junctions & Their Importance

There are three different types of junctions for thermocouples: exposed, grounded, and ungrounded. Each of these serves a different purpose and has different characteristics. Let’s look at each type of junction and where they should be utilized.

...

RTDs, which RTDs is the best one?

Resistance Temperature Detectors (RTDs) available today can generally be categorized into one of two basic types of RTDs, depending on how their temperature sensing element is constructed. One type of RTD contains thin-film elements and the other typ...

Pressure Gauges for Troubleshooting Hydraulic Systems

When it comes to troubleshooting a hydraulic system, nothing is more vital than a hydraulic pressure gauge. Pressure is the heartbeat of the hydraulic system, but monitoring the system operating pressure is not the only function for a pressure gauge....

Information about pressure gauge

A pressure gauge is a fluid intensity measurement device. Pressure gauges are required for the set-up and tuning of fluid power machines, and are indispensable in troubleshooting them. Without pressure gauges, fluid power systems would be both unpred...

How to Calibrate a Thermometer, Step by Step

Learn how to test and adjust your thermometer for absolute accuracy—and you'll instantly become a better cook.

Now more than ever it's important to learn how to calibrate a thermometer. It's the height of summer, after all, and you're going to n...

Digital Pressure Gauges Information

Digital pressure gages are devices that convert applied pressure into signals. Readouts are then displayed numerically.

Many pressure-gauging technologies are available. Devices that use mechanical deflection include an elastic or flexible eleme...

Pressure Gauge Failure: The Top Eight Causes

The humble pressure gauge is an important but often-undervalued component that plays a vital role in reducing the risk of accidents, so when a gauge fails, it can have serious consequences. A failed gauge may lead to the loss of your ability to detec...

Pressure Gauges: Made to Measure

Pressure and flow readings provide a means of assessing the performance of hydraulic and pneumatic systems and aid troubleshooting when malfunctions occur.

The majority of gauges for measuring pressure have one characteristic in common: the pres...

Mechanical vs digital or wireless pressure gauge

Mechanical pressure gauges are simple, cheap devices with local displays that show the pressure at a certain point in your process. This is one of the oldest forms of pressure measurement and it is still very common. Digital pressure gauges seek to b...

6 key Differences Between RTD’s and Thermocouples

1. Measuring Range

The main advantage of thermocouples is their range. Most RTD sensors are limited to temperatures of up to 400-500 °C, and in some cases higher, whereas certain thermocouples can be used to measure above the 1400 to 1800 °C range, ...

THE SCIENCE OF THERMOCOUPLES

we’ve had to learn the fundamentals of certain principles just to understand how to develop something new.

Below is a short story of what we’ve learned about thermocouples, an interesting type of temperature sensor.

So whats the big deal ab...

Digital Pressure Gauges vs. Analog Pressure Gauges

Pressure gauges are essential tools in industrial processes and applications. With the development of digital pressure gauges, people are shifting away from manual analog ones, even though they provide quick and reliable readings.

However, they ...

The Many Types of Pressure Gauges in Measurement Industry

A gauge is essentially an instrument or device for measuring the magnitude, amount, or contents of something, typically with an analog or digital display. This can be a measurement of any property like pressure, flow, temperature, fuel, or length. Th...

How to Choose the Best Digital Pressure Gauges

The technology used in pressure gauges has been around for more than a century, and the pressure gauge is still one of the most common methods of measuring pressure today. The majority of pressure gauges still incorporate the Bourdon tube, socket and...

Liquid vs. Dry Pressure Gauges: What's the difference?

There are two main types of pressure gauges. Today, we will go over why you might consider investing in a liquid filled gauge vs a dry one. Dry pressure gauges are the work horse of the industrial and commercial parts world. Look at most air compress...

Mechanical vs digital or wireless pressure gauge

Mechanical pressure gauges are simple, cheap devices with local displays that show the pressure at a certain point in your process. This is one of the oldest forms of pressure measurement and it is still very common. Digital pressure gauges seek to b...

A Complete Answer To What Is A Pressure Gauge

The measurement of pressure is crucial to the safe and proper functioning of many types of industrial systems and corresponding industrial products. Entire fluid power systems would be unpredictable and unreliable without an accurate way to measure a...

How to Looking Out For the Best Temperature Gauge

A gauge, as specified by its various definitions, can mean a lot of things to diverse users. In order to regulate its exact meaning, you will have to first see at the framework where this word is being used. Temperature gauge is a device that shows t...

What is the working principle of bimetal thermometer?

Bimetal thermometer is a kind of instrument which can directly measure the middle and low temperature of a medium. Its working principle is based on the principle of solid thermal expansion, and two pieces of metal sheets with great difference in exp...

The Significance of Platinum Being utilized to build RTD

RTDs or resistance temperature detectors are ordinarily used to precisely and straightaway measure the temperature of utilizations. These gadgets can be built utilizing different materials, for example, platinum, nickel, copper, nickel-iron, and so f...

Flexibility And Usefulness Of Thermocouples As Sensors Explained

There are a variety of sensors such as RTDs and thermocouples that are used for thermal control and temperature measurement across industries. Maintaining a certain temperature range is crucial for many processes due to the sensitivity of the materia...

Hoe does the water hammer affect pressure gauges and transmitters?

Water hammer is a high tension flood or wave made by the dynamic energy of moving liquid when it is quickly compelled to stop or head in a different path, adjusting the fluid's speed. Quick halting or beginning or altering of course of an in compress...

Correctly Installing Process of Pressure Gauges

1. Select the Right Gauge

Before you take out a wrench, first ensure you have the right sort of check for the application. The strain check you pick should be the right one for the:

• Expected pressure reach to be estimated. The chose reach oug...

What Are the Different Types of Pressure Measurement?

There Are 4 Main Types Of Pressure Measurement

• Gauge – Reference to atmospheric pressure.

• Sealed – Referenced to a sealed chamber closed with atmospheric pressure (approximately 1bar).

• Absolute – The reference is a vacuum (0bar or no pre...

What is Air Pressure?

Our planet is surrounded by air, and this air has mass. So what is air pressure?

The mass of air at 1g force (standard gravity) creates an ambient atmospheric pressure of approximately 1bar (1000 millibar) at sea level.

A typical weather ma...

Diaphragm pressure gauges

Stomach pressure checks, likewise called sealgauges, are appropriate for low tension and overpressure estimating conditions.

Stomach pressure checks are utilized to quantify gases and fluids. They cover estimating ranges from 10 mbar to 40 bars....

PRESSURE GAUGE WORKS

While choosing a tension transducer, or an advanced strain check, it is essential to comprehend pressure types, and how they perform in more favorable conditions.

We have previously given an outline of each tension kind, and covered outright and...

A Beginner’s Guide for Installation of Thermowell

Thermowells play an important role in industrial processes. These are cylindrical tubes used to protect thermal equipment, such as temperature sensors, from direct contact with liquids. Because temperature is an important factor in industrial process...

Why Platinum is a Preferred Choice in RTD Sensors?

Resistance Temperature Detectors, abbreviated RTDs, are wire and thin film devices widely used to measure temperature in laboratory and industrial processes. Equipment made of a thin layer of metal on a ceramic substrate is reliable and can provide a...

What do the thermocouple wire color codes mean?

Most nations fostered their own thermocouple wire variety codes quite a while back. Today, there are two administering bodies that are around the world perceived for setting the acknowledged variety codes guidelines: ASTM International (previously kn...

The ABC’s of thermocouple wire calibration types: What do they mean?

With regards to thermocouple wire, there's a genuine letter set of adjustment types accessible: K sort thermocouple, J type thermocouple, T type, etc. We're oftentimes inquired: What do these assignments mean and which type is appropriate for a parti...

Top Three Reasons To Use a Thermowell

Estimating temperature is a significant piece of any modern interaction framework activity. Tragically, thermometers are not intended to endure particularly cruel conditions. All thermometers are vulnerable to harm from stream, consumption, scraped s...

Purposes behind Choosing a Liquid-Filled Industrial Pressure Gauge

Fluid filled measures outperform dry checks for two principal reasons: execution and expanded help life. Pressure checks that are loaded up with a fluid, normally glycerin or silicone oil, perform preferred in less-over ideal circumstances. They are ...

Thermocouple and It's Working principal?

A thermocouple sensor is one of the many sorts of temperature detecting gadgets utilized in estimating various factors in industry applications. They are frequently utilized for temperature estimation and control at gas turbine depletes, diesel motor...

Fact to Know about Diaphragm pressure gauges

Stomach pressure checks, additionally called seal gauges, are reasonable for low tension and overpressure estimating conditions.

Stomach pressure checks are utilized to quantify gases and fluids. They cover estimating ranges from 10 mbar to 40 b...

How Mobile Commerce Impacts Industrial Instrumentation

Individuals are getting unimaginably effective with their telephones. Strangely, it's how much happy they consume, yet what they really do on their telephone. Clients can type 38 words each moment on their telephone just 25% more slow than actual con...

What Is Calibration?

Instrument alignment is one of the essential cycles used to keep up with instrument precision. Alignment is the most common way of designing an instrument to give an outcome to an example inside a satisfactory reach. Disposing of or limiting elements...

Thermocouple styles: probe, wire or surface?

Since a thermocouple can take many shapes and structures, it is critical to comprehend how to choose the right sensor accurately. The most ordinarily measures used to go with that decision are the temperature range, the synthetic obstruction, the scr...

A Quick Tutorial of Thermocouples Works

Thermocouples are electrical gadgets used to gauge temperature. Their precision, fast response time, and capacity to endure weighty vibrations, high tension, and outrageous temperatures make them ideal for a wide scope of uses. Be that as it may, how...

hammer affect on pressure gauges and transmitters?

Water hammer is a high strain flood or wave made by the motor energy of moving liquid when it is quickly compelled to stop or head in a different path, changing the fluid's speed. Fast halting or beginning or shifting of course of an in compressible ...

The heroes of Industry Pressure gauges

Realizing which style of strain measure is ideal for your liquid power framework is basic in guaranteeing predictable, proficient activity.

Pressure checks are unrecognized yet truly great individuals in numerous water driven frameworks. They ar...

The Pros and Cons of Disposable Pressure Gauges

The technique for overseeing pressure measures can frequently spike a solid discussion. Some say that utilizing great tension checks with ordinary adjustment is fundamental to limiting margin time, while augmenting cGMP consistence and efficiency. Ot...

Which Tyre Pressure Gauge Is Best?

Keeping the right tire pressure is vital to guard your vehicle on street. It doesn't simply assist with further developing the efficiency of a vehicle, yet diminishes the gamble of blown outs and mishaps. If you have any desire to keep your new tires...

Pressure gauge with reed switch

Miepl has acquainted another security include with one of its well known and believed high-immaculateness pressure gauges.

Miepl has acquainted another security include with one of its well known and believed high-immaculateness pressure gauges....

Product Focus: Digital pressure gauge

Miepl Digital Pressure Gauge includes an extraordinary PSV mode intended to test pressure security and help valves.

Miepl Digital Pressure Gauge includes an extraordinary PSV mode intended to test pressure security and help valves. When the valv...

Repair and Refurbishment Services for Diaphragm Seals and Pressure Gauges

Pressure measures and stomach seals are frequently utilized with poisonous and destructive media. By utilizing proper materials during fabricate you can restrict the harm that liquids and gases can cause to stomachs and pressure measures. Extra time,...

When to Use Diaphragm Seals

Utilized as defensive gadgets intended to disconnect pressure checks, pressure transmitters, and tension changes from possibly harming process media, stomach seals give compelling answers for safeguarding pressure instruments when and whenever applie...

What Causes Temperature Sensors to Fail?

Modern temperature sensors, whether platinum temperature sensors, thermocouples, thermistors, or others, can be powerless against disappointment at times. Treating the temperature sensors appropriately goes far in keeping up with their precision, how...

Reasons to Use a Thermowell

Assuming that you oversee or possess a business office with large equipment, you definitely realize that keeping your hardware moving along as expected is a sensitive cycle. In the event that one piece of the hardware gets too hot, the entire machine...

Overview and Working Principle of Absolute and Gauge Pressure Transmitters

Throughout the long term, pressure transmitters are used to gauge fluid degrees of open or compressed tanks in modern cycles. With fast digitalization, these transmitters currently involve cutting edge innovation and worked on extra elements. This he...

How to Install Pressure Gauges Correctly

1. Select the Right Gauge

Before you take out a wrench, first ensure you have the right sort of check for the application. The strain check you pick should be the right one for the:

• Expected pressure reach to be estimated. The chose reach oug...

Thermocouple probe, wire and More?

Because a thermocouple can take many shapes and forms, it is important to understand how to correctly select the right sensor. The most commonly criteria used to make that choice are the temperature range, the chemical resistance, the abrasion and vi...

Which Factors to Affect the Pressure Gauge Accuracy?

Pressure check utilizes flexible parts, (for example, bourdon tube, diaphragm) as delicate parts, estimating and demonstrating the tension worth over the encompassing strain, the application is very normal, it is utilized in practically all modern cy...

How to do Troubleshoot of Pressure Gauges and Impulse Lines

Automation professionals are confronted every day with obstacles caused by outdated instrumentation technologies and practices. When first installed, these solutions were likely state-of-the-art and improved existing installations, but many have now ...

How to Install Pressure Gauges Correctly

1. Select the Right Gauge

Before you take out a wrench, first ensure you have the right sort of check for the application. The strain check you pick should be the right one for the:

• Expected pressure reach to be estimated. The chose reach oug...

Digital vs wireless or Mechanical pressure gauge

Mechanical pressure gauges are simple, cheap devices with local displays that show the pressure at a certain point in your process. This is one of the oldest forms of pressure measurement and it is still very common. Digital pressure gauges seek to b...

7 CONSIDERATIONS FOR MECHANICAL SEAL SELECTION

Mechanical seals can work for a long time without issue, for however long they've been appropriately chosen for their application. One should distinguish the application information (or working circumstances) to appropriately choose the kind of seal ...

STAINLESS STEEL THERMOWELLS: FUNCTIONS AND TYPES EXPLAINED

Thermowells are a brilliant choice for further developing the help life of sensors used to screen channeling processes. Be that as it may, as most channeling parts, picking the appropriate plan and fit for your expected application is fundamental to ...

When Should I Use a Coated Thermowell?

Thermowells are utilized to shield your temperature estimation instruments from the components, and that implies they are frequently presented to outrageous conditions and temperatures. Safeguarding the thermowell can assist with keeping your tempera...

5 ways to detect and prevent pressure gauge failures before they happen

Regardless of the business, interior interaction pressure is a basic exhibition marker for a modern liquid framework. Too low or too high tensions can cause an adverse consequence on item yield and quality and might possibly make a security risk for ...

6 tips for maintaining industrial fluid system safety

Following laid out accepted procedures for the plan, establishment and activity of modern liquid frameworks can assist with upgrading security plantwide.

Across a scope of worldwide interaction driven enterprises, modern liquid frameworks convey...

Tips on Looking Out For the Best Temperature Gauge

A measure, as indicated by its different definitions, can mean a ton of things to assorted clients. To manage its definite importance, you should initially see at the system where this word is being utilized. Temperature measure is a gadget that show...

The Right Thermometer for Your Application

There are different mechanical estimating standards for deciding temperature. However, while choosing a reasonable thermometer, it isn't just the estimating standard which assumes a part, the sort of estimating instrument is likewise significant. In ...

WHY INSTALLING AN OIL PRESSURE GAUGE IS IMPORTANT?

It isn't just about the oil pressure gauge. Whether you will introduce an oil pressure gauge or a Tridicator Gauge, you need to know the legitimate strategy of introducing them regardless.

An oil pressure gauge is normally introduced on the dash...

WHAT IS AN INDUSTRIAL GLASS THERMOMETER?

Numerous modern cycles and frameworks produce intensity and should be observed. Controlling the temperature doesn't simply control the climate yet in addition helps safeguard the actual uprightness of the items being fabricated. You want a dependable...

A tutorial on Pressure Gauges – Bourdon tube, Glycerine filled or Liquid-less?

Pressure is normally observed on process destinations from one side of the planet to the other, and one of the instruments used to quantify pressure is the Bourdon Cylinder Pressure Measure. The Bourdon Cylinder is the name given to the mechanical pa...

How to Know If Your Pressure Gauge Is Accurate?

The pressure gauge is perhaps of the most basic part in most handling frameworks. From petrochemical handling to pneumatic gadgets, pressure gauges assume a significant admonition part. Be that as it may, simply having a pressure gauge isn't sufficie...

Which RTDs is the best one?

Resistance Temperature Detectors (RTDs) accessible today can commonly be sorted into one of two essential kinds of RTDs, contingent upon how their temperature detecting component is built. One sort of RTD contains slender film components and the othe...

The 4 Types of Pressure Measurements, and the tools to Measure them

In pretty much every kind of designing, having information on the most proficient method to utilize pressure measurement apparatuses is urgent to the security and trustworthiness of tasks. As per the Worldwide Society of Mechanization (ISA), pressure...

What is a Compound Pressure Gauge and When to Use One?

I just got off the telephone with a person entrusted with buying a compound check, yet he didn't have the foggiest idea what it was or the way that it was not quite the same as a standard pressure measure. I get this call constantly, frequently from ...

How a Differential Pressure Gauge Can Help to Maintain the Air Quality in a Compressed Air System

What is differential pressure?

Differential pressure (DP) alludes to the distinction between two applied places of pressure. At the point when this worth will in general vacillate essentially in a cycle system, it very well may be a sign that the pa...

When you should Use Diaphragm Seals

Utilized as defensive gadgets intended to disconnect pressure checks, pressure transmitters, and tension changes from possibly harming process media, stomach seals give compelling answers for safeguarding pressure instruments when and whenever applie...

Pressure And Temperature Gauge

Pressure and temperature gauge is additionally called tridicator. This is a multi-practical gauge that actions pressure and temperature at same time in one gadget.

This item is to check pressure and temperature level from gas, air, and water app...

Why Platinum is a Preferred Choice in RTD?

Resistance Temperature Detectors, shortened as RTDs are wire wound and slender film gadgets that are broadly utilized to quantify temperature in laboratory and modern cycles. The gadget, which is made of meager layer of metals on a clay substrate, is...

What are the Steps Involved in Calibrating Pressure Gauge?

Today, various transmitters are being utilized to quantify boundaries, like temperature, pressure, stream, level, and so forth. An instrument, which is utilized to quantify the pressure of a liquid is alluded as a pressure gauge. These gauges are uti...

What is a Bellows Pressure Gauge?

Bellows are covers generally made of elastic or metal to shield modern machines and gear from outside harm, spillage, etc. They increment the effect strength of the machines and furthermore their functional life. All in all, what is a bellows pressur...

A Guide to Choosing a Digital Pressure Gauge

While picking a digital pressure gauge you genuinely should check out at every one of the distinctions between the different choices. Here is an enlightening manual for assist you with picking the best digital pressure gauge to meet your requirements...

HOW DOES A VACUUM PRESSURE GAUGES WORKING

Vacuum Gauges where the Pressure Readings are Independent of the Type of Gas (Mechanical Vacuum Gauges)

Bourdon Vacuum Gauge

The inside of a tube which is bent into a circular arc (the so-called Bourdon tube) is connected to the vacuum system. ...

WHY YOU SHOULD USE DIFFERENTIAL PRESSURE GAUGES?

How differential pressure gauges influence the success of process control applications with many measurement variables.

In the world of process control there are many measurement variables, generally falling under the categories of pressure, tem...

Flushing rings in diaphragm seal systems have several advantages

Diaphragm seal frameworks are utilized in processes with basic media. During some cycle steps, for example, closing down and chilling off the cycles, media adheres to the diaphragm of the diaphragm seal. This outcomes in estimation mistakes and, in t...

Diaphragm seal system detects level in PTA reactors

Diaphragm seal frameworks are great for some cycles in the synthetic business as a safe and safe estimating arrangement, for instance, to screen the level in a reactor utilizing differential tension. Exactly for this errand, a producer of terephthali...

Effects of Temperature on Pressure Gauges

Effects of Temperature

Changes in ambient temperature affect the accuracy of gauges in several ways. Range shift is caused by the change in modulus of elasticity of the bourdon. This effect increases proportionately as the pressure increases. As a g...

CALIBRATION PROCESS OF MANOMETER

A manometer is a tool to measure pressure in closed systems. Manometers measure different types of pressure, absolute, gauge, and differential. They

generally come in two types, liquid and elastic. These types in turn divide into several models:

...

Absolute and Gauge Pressure Transmitters